Fengwei Shan, Beiguan Town, Yangjiang,China

zip code :

529932phone :

+86 13160522883Fax :

+86 13160522883Email :

esales@kitsen.com

Fengwei Shan, Beiguan Town, Yangjiang,China

zip code :

529932phone :

+86 13160522883Fax :

+86 13160522883Email :

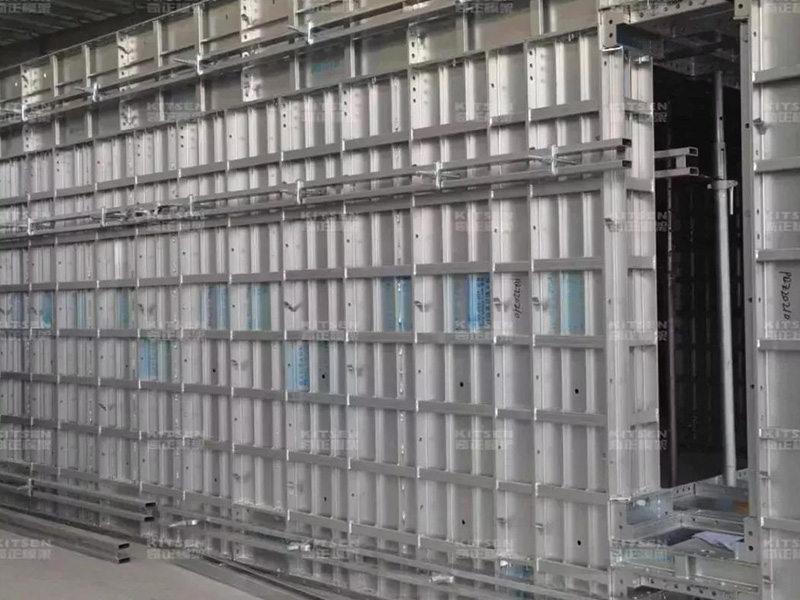

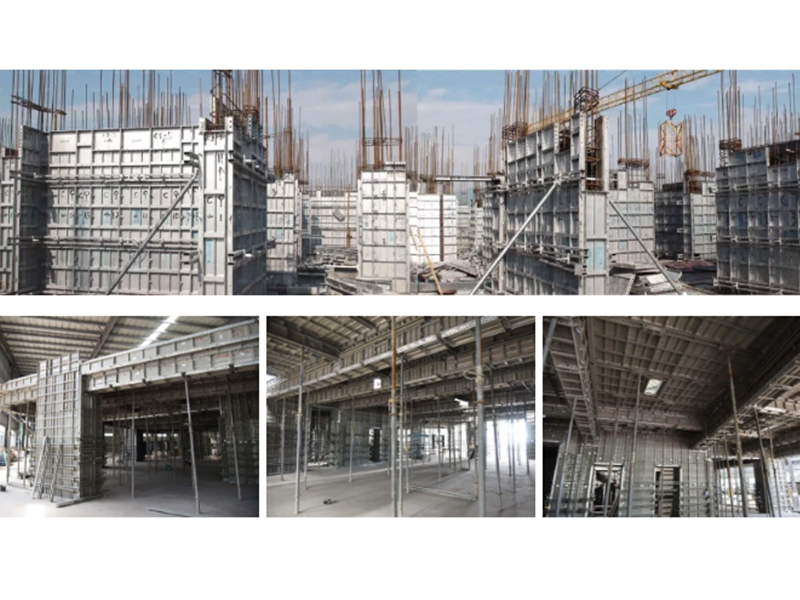

esales@kitsen.comThe most widely used formwork support is aluminum formwork support, because the advantages of aluminum alloy formwork are very significant, not to mention simplification of construction difficulty, energy saving and emission reduction, and environmental protection. Let's take a look at the construction process requirements of aluminum formwork. This is very important.

1. Construction measurement and release: The axis, side line and 30 control lines of the wall column were measured and clearly marked. After the wire is loosened, visually check whether the wall reinforcement is on the side line, and leave a corresponding protective layer.

2. Use level to measure whether the flatness of the concrete floor is controlled within 8mm. If it exceeds this range, it must be trimmed accordingly. In addition, when pouring concrete, the root of the aluminum mold is easy to rot and leak.

3. Before installing the formwork, the surface of the concrete poured on the construction joint should be chiseled, leaked, and cleaned. The horse stool iron is made of Φ16 steel bars and is used for the embedded parts of the inclined roof.

4. Before installing external walls, elevator shafts and lighting shafts, the connecting layer between the wooden mold and the aluminum mold should be expanded at an elevation angle, and the steel rods should be punched to start positioning (especially bay windows are the most easily deformed).

5. A uniform brush release agent should be used before the template is supported. In order to prevent excessive release agent from flowing into the ground, the upper and lower half of the template should be brushed freely and evenly. It is strictly forbidden to brush off the waste oil on the surface of the aluminum mold. .

6. Welded wall positioning ribs, the position of the wall positioning ribs should meet the following requirements:

① There should be positioning ribs at the ends and corners of the wall, the positioning ribs shall not be less than Φ10, and the horizontal spacing shall not exceed 450 mm.

②The end of the shear wall should be provided with a concrete inner support every 900mm along the height direction to ensure the size of the screenshot of the shear wall.

③The exterior walls, lighting shafts, and elevator shafts of the joint between the wooden mold and the aluminum mold should use resilient high-wire steel rod positioning piles to support the aluminum mold.

Before construction, it is necessary to comprehensively check whether the aluminum formwork is defective. Because the assembly accuracy of the aluminum formwork is very high, it must be implemented in strict accordance with the implementation standards during the operation.

The core advantages of KITSEN Aluminum Formwork

1. Long service life, the average service life of aluminum alloy template can reach 300-500 times or more.

2. All structures are assembled with aluminum alloy template. After the assembly is completed, an overall frame is formed with good stability and high bearing capacity.

3. The top mold and the support system have realized an integrated design, and the early disassembly technology is integrated into the top support system, which greatly improves the turnover rate of the formwork.

4. There are relatively few aluminum formwork support rods, large on-site operation space, unobstructed personnel, and convenient material handling, which greatly improves on-site management efficiency.

5. After the aluminum alloy formwork system is demolished, the surface quality of the concrete is smooth and clean, achieving the effect of finishing fair-faced concrete.

6. A wide range of applications, suitable for housing construction, infrastructure, water canal tunnels, etc.

Copyright © 2020 KITSEN Scaffold&Formwork Official All Rights Reserved.粤ICP备20064098号

XMLthe professional team to service !